Red Wing Made - Tanning

All Red Wing leather comes from our own tannery, S.B. Foot Tanning Company, located in Red Wing, Minnesota.

Transforming hides into leather is an art form. Preparation begins by soaking each hide in a wood drum with tree oils,

tanning agents and dyes. The hides can be finished in a number of ways to achieve a desired texture and level of

pliability and water resistance.

With a little maintenance every so often, properly tanned boots will perform and protect for many years.

S.B. Foot uses fresh-prepared hides referred to as wet blues. The name refers to the bluish hide color results from our

high-exhaustion tanning process that produces a highly stable, pliable and durable material. It is the ideal starting

point for what ultimately becomes a premium-grade leather.

Jeff Dols has been at Red Wing for 33 years. He is the first set of eyes that scours every inch of nearly every hide that arrives at the S.B. Foot Tannery.

The quality of our leather rests heavily on Jeff's shoulders. He assigns the leather grades. He looks for weak spots and the slightest of imperfections. He is the gatekeeper who makes sure only the finest leather goes into every Red Wing boot that goes out into the world.

Jeff Dols has been at Red Wing for 33 years. He is the first set of eyes that scours every inch of nearly every hide that arrives at the S.B. Foot Tannery.

The quality of our leather rests heavily on Jeff's shoulders. He assigns the leather grades. He looks for weak spots and the slightest of imperfections. He is the gatekeeper who makes sure only the finest leather goes into every Red Wing boot that goes out into the world.

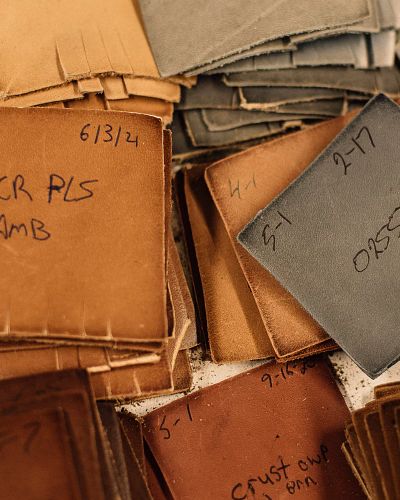

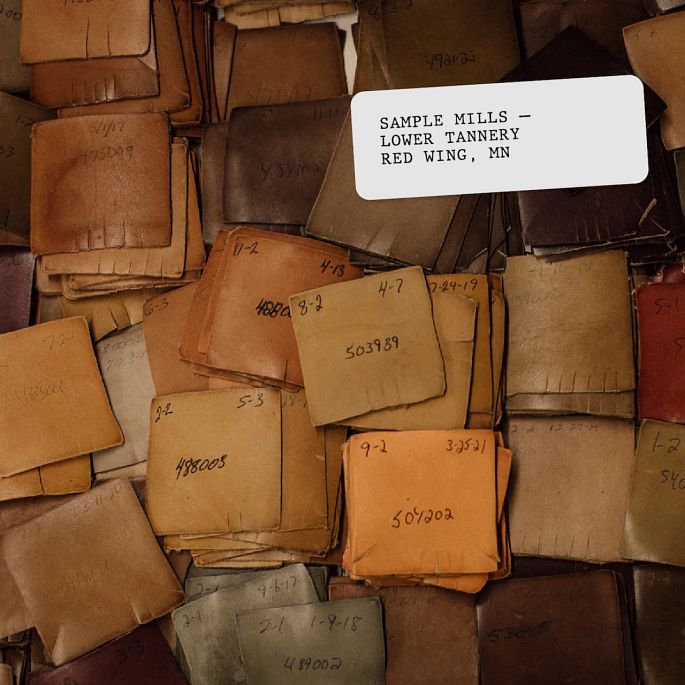

To achieve the unique, rich leather colors we offer, each hide is carefully tested and sampled prior to finishing. Scott

Johnson has worked at Red Wing for 38 years, 20 of which have been spent in the sample mills at the S.B. Foot Tannery.

Every day is different in the sample mills as Scott and his team pull hides, test formulas and make sure that each and every piece matches one another perfectly within an intended color.

Scott says it is this variety that he enjoys most about the work. Sometimes it takes many samples to get the colors matched up. Sometimes you get it right the first time. You just never know — and that's the beauty of it.

Every day is different in the sample mills as Scott and his team pull hides, test formulas and make sure that each and every piece matches one another perfectly within an intended color.

Scott says it is this variety that he enjoys most about the work. Sometimes it takes many samples to get the colors matched up. Sometimes you get it right the first time. You just never know — and that's the beauty of it.

To achieve the unique, rich leather colors we offer, each hide is carefully tested and sampled prior to finishing. Scott

Johnson has worked at Red Wing for 38 years, 20 of which have been spent in the color mills at the S.B. Foot Tannery.

Every day is different in the color mills as Scott and his team pull hides, test formulas and make sure that each and every piece matches one another perfectly within an intended color.

Scott says it is this variety that he enjoys most about the work. Sometimes it takes many samples to get the colors matched up. Sometimes you get it right the first time. You just never know — and that's the beauty of it.

Every day is different in the color mills as Scott and his team pull hides, test formulas and make sure that each and every piece matches one another perfectly within an intended color.

Scott says it is this variety that he enjoys most about the work. Sometimes it takes many samples to get the colors matched up. Sometimes you get it right the first time. You just never know — and that's the beauty of it.

After only four years, Frank Lin has earned the nickname of "jack of all trades" by his peers in the S.B. Foot Tannery

finishing department.

Frank applies his experience and Engineering degree from Duke University to navigate both the art an the science of finding the right finishing treatment mixture. Because no two hides are identical, finishing has a definite "feel" to it for finding that perfect balance of formula, wax and oil to get the best end result possible.

Frank applies his experience and Engineering degree from Duke University to navigate both the art an the science of finding the right finishing treatment mixture. Because no two hides are identical, finishing has a definite "feel" to it for finding that perfect balance of formula, wax and oil to get the best end result possible.

"We are a part of something that is much bigger than us or the leather. When I throw hides, I try to put good vibes on

every one of them because they end up in all these other countries around the world. What we do has meaning to a lot of

people in their daily lives."

- JOCELYN GOODELL, LEATHER FINISHING

Fred Oekler stands in front of the final step at the end of the line, where he makes one last pass to closely inspect

every hide before it gets approved for use in our boots.

Fred inspects up to 1,000 hides every day — and he's not afraid to pull a piece for even the slightest flaw or defect. Fred's brother Abe Oekler is another stickler for quality. The two work just steps away from each other in the finishing area.

Fred inspects up to 1,000 hides every day — and he's not afraid to pull a piece for even the slightest flaw or defect. Fred's brother Abe Oekler is another stickler for quality. The two work just steps away from each other in the finishing area.

Fred Oekler stands in front of the final step at the end of the line, where he makes one last pass to closely inspect

every hide before it gets approved for use in our boots.

Fred inspects up to 1,000 hides every day — and he's not afraid to pull a piece for even the slightest flaw or defect. Fred's brother Abe Oekler is another stickler for quality. The two work just steps away from each other in the finishing area.

Fred inspects up to 1,000 hides every day — and he's not afraid to pull a piece for even the slightest flaw or defect. Fred's brother Abe Oekler is another stickler for quality. The two work just steps away from each other in the finishing area.